WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

TEXTILE BALER

Note: Textile Baler with Rear Chute and Conveyor configuration has been discontinued

For Textile Baler less the Conveyor & Automated Rear Chute click here

For High Volume Baling with Conveyor & Automated Rear Chute click here

Textiles are not only recycled to be reused in their original form. They are also recycled into other products such as mattresses, speaker cones, car insulation, furniture padding, and other items. Types of textiles that can be considered for recycling are clothes, furniture upholstery, carpet, sheets, towels, and some footwear. This textile baler with an automated rear chute and conveyor will streamline your textile recycling operation, creating the most efficient baling and recycling operation possible.

60CC-207T - BALER FOR TEXTILES / CLOTHES (Discontinued)

Request Info on Multiple Products - (Secure Area)

This 60" High Volume Textile Baler was designed specifically for Clothing / Textiles.

With a 7" Cylinder and plenty of Horsepower and platen force this baler can produce up to 3 bales per hour at up to 1,200 to 1,400 pounds per bale. The baler comes standard with an automated rear chute and a conveyor.

When your main focus is on baling Textiles and clothing, this High Volume, High Capacity Textile Baler is the right choice.

Textile Baler Performance Information |

|||

Bale Size |

30” x 48” x 60” |

||

Bale Volume |

50 Cubic Feet |

||

Cycle Time |

55 Seconds (No Load) |

||

Estimated Bale Weights |

|||

Material |

Bale Weight |

Density Lbs/Cu Ft Loose/Baled |

Bales / Hr |

Textiles |

Up to 1,200 - 1,400 Lbs |

4 / 28 |

Up to 3 |

Note: Performance Rates, Bale Weights, and Bale Densities are subject to many factors such as Material Pre-Bale Densities, Feed rates, Moisture Content and other variables. |

|||

Textile Baler - Hydraulics |

|

Main Pumps |

16.1 GPM - Fixed Volume Vane |

System Pressure |

2600 psi |

Main Cylinder |

7” Bore, 4.5” Rod, 48” Stroke |

Ram Face Pressure |

61.61 psi |

Overall Platen Force |

100,048 Lbs |

Oil Reservoir |

41 Gallon Capacity |

Hydraulic Manifold |

D05 Pattern, Internal Relief Valve Subplate Circuit |

Feed Chute Cylinders |

2.5” Bore, 10” Stroke, 1 3/8” Rod |

Textile Baler - Electrical |

|

Main Motor |

20 HP - 208v / 230v / 460v – 3 Phase |

Enclosure |

NEMA 1 Gasketed |

Controls |

UL/CLU Listed CSA - PLC Controlled |

Motor Type |

TEFC High Efficiency |

Textile Baler - Dimensions & Structural |

|

Overall Height |

150 |

Overall Width |

80 |

Overall Depth – Main Unit |

87 |

Overall Depth w Conveyor |

300” |

Feed Opening |

27” x 60” Charge Dimensions |

Weight |

12,000 lbs – Baler Only (+ Conveyor @ 5,000 lbs) |

Textile Baler - Conveyor Specs |

48" Wide Belt, 150 PVC w/rubber cleats on 48" centers |

1.5 HP Motor - 208v / 230v / 460v - 3 PH |

Conveyor Controls are in Baler Control Panel |

Approximate 2 Cubic Yard Hopper with a width of 60" |

18" Conveyor sides |

Enclosed return pan |

| Conveypr Speed - 35 FPM |

High Volume Textile Baler |

Safety - UL / CLU Listed CSA - PLC Controlled |

| Product meets or exceeds all ANSI Z245.5 and OSHA standards. |

| NEMA 1 Gasketed |

| Bale Height Adjustable from 42" - 48" Nominal |

| Safety Interlock Circuit on Bale Door & Safety Gate |

| Counterbalanced Feed Door for Easy Open |

| 3-6" Retainer Dogs Front & Back |

Soft Shift, Low Shock Hydraulic Circuit |

| Dual Chain Semi-Automatic Bale Ejection System |

| Factory Wired for Easy Installation |

| Slotted Front Door (available as an option) |

| Automated Photo-Eye operated read feed chute |

| Manually operated cycle to assure level load in feed chamber |

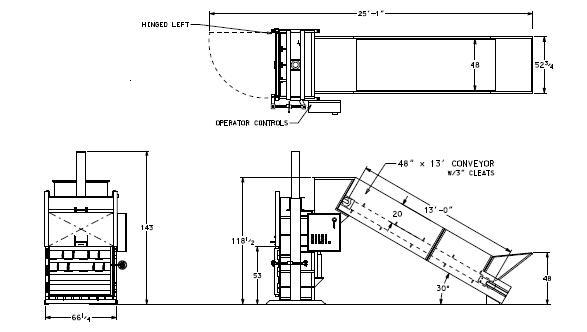

60CC-207T High Volume Textile Baler - Diagram

(with Automated Rear Chute & Conveyor)

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF