WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

SUPER HIGH VOLUME INDUSTRIAL BALERS

Plus Automated Rear Chutes & Conveyors

This baler can be used for a variety of applications. Manufacturing facilities, Recycling plants, Warehouses, and more. This baler can bale almost anything including cardboard, plastics, metals, cans, newsprint and textiles. The convenient conveyor drops the material directly into the baler, making it easy to streamline your baling operations.

SUPER HIGH VOLUME BALER SERIES

60CC-3010 - (Automated Rear Chute & Conveyor)

60C-3010 - (Automated Rear Chute - No Conveyor)

60-2010 - (Baler only - No Rear Chute / Conveyor)

Request Automated Response with general pricing:

60CC-3010 -

60C-3010

-

60-2010

Request Info on Multiple Products - (Secure Area)

This 60" Super High Volume Baling System is ideal for:

- Recycling Centers

- Transfer Stations

- Large Warehouses / Distribution

- Large Institutional Applications

- Manufacturing Facilities

- Large Retail / Shopping Centers

- Large Educational Campuses

- Large Hotels & Resorts

- Military Bases

- Other Large Industrial and Commercial Applications.

This Super High Volume Baler is so Loaded with Incredible Power & Features, you won't even think about a Horizontal Baler.

- Forget about the high cost of a Horizontal Baler

- Forget about costly material pre-conditioning

- Forget about the huge operating area required by a Horizontal Baler

This Baler is a production workhorse that is built for super high volume output . With a 10" Cylinder, 30 HP Motor and 30 Second Cycle Time, and many other features, this baler will produce big results fast. It is loaded with standard features which includes a conveyor fed automated rear chute. Simply load recyclables in the Conveyor Hopper (which is 48" off the floor for extra safety) and watch this baler work. When the bale needs to be removed, the rear chute automatically closes until the bale is removed. Quickly turn a truckload of loose recyclables into dense, high value bales. With over 235,000 pounds of platen force it will process a large variety of the toughest recyclables into dense bales.

The door is opened and closed by a hydraulic cylinder with a damper controlled feed chute. (When coupled with a conveyor, the Automatic Rear Chute is used to feed the baler PET bottles, used beverage containers, aluminum cans and more).

60CC-3010 bales a variety of materials such as:

- Cardboard

- PET

- HDPE

- Shrink Wrap

- Steel and Aluminum Cans

- Foam

- Other materials such as Magazines, ONP & Waste Paper

- More...

With the fast cycle time, you can make 2 to 3 dense cardboard bales weighing approximately 1,500 pounds each in less than an hour. Or you can make can 1 or 2 dense bales of PET weighing approximately 1,000 pounds each. Literally take truckloads of recyclables and turn them into 1or 2 dense bales in less than an hour.

60CC-3010 Baler Specifications & Dimensions

Super High Volume Baler Performance Information |

|||

Bale Size |

30” x 48” x 60” |

||

Bale Volume |

50 Cubic Feet |

||

Cycle Time |

30 Seconds (No Load) |

||

Estimated Bale Weights |

|||

Material |

Bale Weight |

Density Lbs/Cu Ft Loose/Baled |

Bales / Hr |

OCC – Cardboard |

Up to 1,300 - 1,450 Lbs |

2.5 / 30 |

2 – 3 |

Magazine / Newsprint |

Up to 1,600 Lbs |

3.5 / 33 |

2 – 3 |

PET |

Up to 1,000 Lbs |

1 / 18 |

1 – 2 |

UBC – Aluminum Cans |

Up to 800 Lbs |

1 / 24 |

1 – 2 |

Steel Cans |

Up to 1,200 Lbs |

1 / 20 |

1 – 2 |

HPDE |

Up to 1,200 Lbs |

1 / 20 |

1 – 2 |

Polyurethane Foam |

Up to 850 Lbs |

1 / 20 |

1 – 2 |

Plastic Film |

Up to 1,100 Lbs |

1 / 15 |

1 – 2 |

Halofil Fiber |

Up to 700 Lbs |

1 / 20 |

1 – 2 |

Painted Sheet Metal |

Up to 1,500 Lbs |

3 / 30 |

1 – 2 |

Aluminum Radiators |

Up to 1,600 Lbs |

4 / 30 |

1 – 2 |

Copper Tubes / Wires |

Up to 2,700 Lbs |

4 / 30 |

1 – 2 |

Note: Performance Rates, Bale Weights, and Bale Densities are subject to many factors such as Material Pre-Bale Densities, Feed rates, Moisture Content and other variables. |

|||

*Super High Volume Baler Hydraulics |

|

Main Pumps |

47.95 GPM - Double Vane |

System Pressure |

3000 PSI Maximum |

Main Cylinder |

10” Bore, 7” Rod, 52” Stroke |

Ram Face Pressure |

145 PSI |

Overall Platen Force |

235,620 Lbs |

Oil Reservoir |

150 Gallon Capacity |

Hydraulic Manifold |

2 - D08 Pattern Dir Valves, Pump Mounted Relief and Unloading |

Door & Feed Chute Cylinders |

3.5” Bore, 10” Stroke, 2” Rod / 2.5” Bore, 10” Stroke, 1 3/8” Rod |

*Super High Volume Baler Electrical |

|

Main Motor |

30 HP - 230 / 460v – 3 Phase |

Enclosure |

NEMA 12 - Rated |

Controls |

UL Listed - PLC Controlled |

Motor Type |

TEFC High Efficiency |

Photocell |

LED Type |

*Super High Volume Baler - Dimensions & Structural |

|

Overall Height |

155 |

Overall Width |

85 |

Overall Depth – Main Unit |

87 |

Overall Depth w Conveyor |

300” |

Feed Opening |

30” x 64” |

Weight |

16,000 lbs – Baler Only (+ Conveyor @ 5,000 lbs) |

*Other Features of the Super High Volume Baler |

UL Listed Controls - Electrical Panel and Control Assembly |

| Product meets or exceeds all ANSI Z245.5 and OSHA standards. |

| Product has NEMA 12 |

| Extended Platen Guide Tubes |

| Safety Interlock Circuit on Bale Door & Safety Gate |

| Counterbalanced Feed Door for Easy Open |

| Retainer Dog System |

Soft Shift, Low Shock Hydraulic Circuit |

| Semi-Automatic Bale Ejection System |

| Factory Wired for Easy Installation |

| Extra reinforced framing |

| Tube Type Platen Guide System |

Note: This baler can also be ordered as a stand alone without the Automated Rear Chute or Conveyor which is ideal in a situation where space is at a premium and you need the extremely high capacity of this Baler for bulky materials such as corrugated boxes which can be fed through the front loading door. This Baler (Model 60-2010 only) comes standard with a 20 HP instead of 30 HP.

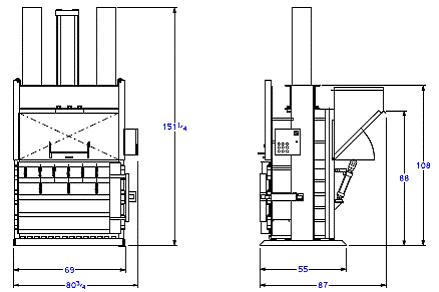

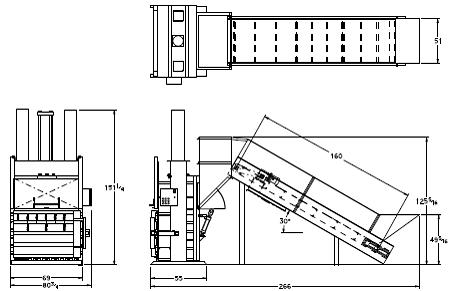

Super High Volume Baler Diagrams

60C-3010 - Automated Rear Chute only (without Conveyor)

60CC-3010 Automated Rear Chute with Automated Rear Chute & Conveyor

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF