WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

FOAM, FILM, FIBER BALERS (& CARPET SALVAGE) Baler

60" Vertical Baler

Large bale loads are no problem for this baler. The 'memory' or bounce-back of foam, plastics and other materials is easily handled with this workhorse of a baler. This baler leaves a high-density bale ready for recycling or sale of reusable materials.

60V-15FM - FOAM, FILM, FIBER BALER

Request Automated Response with general pricing - (Secure)

Request Info on Multiple Products - (Secure Area)

This Specialty Baler is ideal for applications involving the baling of Foam, Film, Fiber & Carpet Salvage.

This baler is ideal for:

- Manufacturing Facilities

- Shopping Centers

- Supermarkets

- Department Stores

- Colleges & Universities

- Hotels / Motels

- Military Bases

- Recycling Centers

- Transfer Stations

- Many other types of Industrial / Commercial Applications

Click here

to check out the different balers and the bale weights they produce on

various materials

The Foam / Film / Fiber Balers (or 'High Memory' Material Balers) have many important design features

that separate them from other standard or multi-use balers.

- Bale weights are heavier which means lower hauling costs and better transport efficiencies.

- When compared to a standard baler or even a high density baler that is trying to bale Foam, Fiber or Film, these High Memory specialty balers can produce a heavier, denser bale of foam, film, fiber or carpet salvage in about one-fourth or even one-fifth the time of the standard baler.

- The High Memory Material Balers use a longer cylinder and stroke so that more air is forced out from the foam, film or fiber as the material is compressed. Thus, the longer stroke provides bale densities that are much higher.

- As the Film, Fiber, Foam is compressed there is 'memory' and retention factors that must be addressed which cannot be handled properly with a standard baler (such as a cardboard baler). Special retention dogs (in conjunction with other unique features) help to overcome these critical elements.

- The High Memory Material Balers also have special sheering capabilities not found on standard balers. Integrated in these balers is a specially designed 'Sharks teeth' component that serves as both a sheering mechanism and a serrated knife that rips through the foam, film and fiber.

- Special design considerations help keep the material from becoming wedged or trapped in the baler (which could otherwise cause jamming).

- In-feed openings are larger than the size of the typical baler openings. Oftentimes the smaller in-feed openings mean that a shredder must be added to the baling system in order to reduce the size of the (material) particulates being baled.

- The High Memory Material Balers are also designed with a tapered chamber area (which is different from the standard taper) so that the bales are released with more ease. This modified taper is another feature that sets these specialty balers apart from the typical baler.

- In addition to the above overview, there are many other differences in the design that separate these Specialty Vertical balers from other balers (some of which are proprietary features).

For Foam Recycling, Film Recycling, Fiber Recycling and processing Carpet Salvage, these specialty 'High Memory Balers, are an excellent choice. In order to be effective on this class of high memory materials, the design and functionality is significantly different than that of the multi-use balers, standard balers or even the high density balers.

Foam, Film, Fiber Balers can:

- Reduce waste disposal costs (since the material is removed from waste stream)

- Reduce labor costs associated with the handling of this material during disposal.

- Generate revenues from the sale of the recycled materials.

- Streamline overall waste processing operations.

- Help with the reduction of fire hazards (due to accumulation of materials)

- Help improve workplace safety and neatness.

Foam Film Fiber Balers - Performance Information |

|||

Bale Size 60V-15FM-BS |

30” x 48” x 60” |

||

Bale Volume 60V-15FM-BV |

50 Cubic Feet |

||

Cycle Time 60V-15FM-CT |

52 Seconds (No Load) |

||

Estimated Bale Weights |

|||

Material |

Bale Weight |

Density Lbs/Cu Ft – Loose/Baled |

Bales / Hr |

Carpet Salvage |

Up to 825 lbs. |

4 /17 |

1.5 |

Carpet Rebond Foam |

Up to 750 lbs. |

2 / 22 |

2 |

Polyethylene Film Scrap |

Up to 700 lbs. |

2 / 20 |

2 |

Polyethylene Foam |

Up to 700 lbs |

1.75 / 5 |

1.25 |

Corrugated Cardboard |

Up to 1,100 lbs. |

2.5 / 24 |

2 |

Shredded ONP |

Up to 1200 lbs. |

2 / 26 |

2 to 3 |

Foam Film Fiber Balers - Hydraulics |

|

Main Pumps 60V-15FM-MP |

9.6 GPM @ 1,800 RPM Fixed Volume Vane |

System Pressure 60V-15FM-SP |

2600 PSI Maximum |

Main Cylinder 60V-15FM-MC |

6” Bore, 3.5” Rod, 52” Stroke |

Ram Face Pressure 60V-15FM-FP |

45.26 PSI |

Overall Platen Force 60V-15FM-PF |

73,502 Lbs |

Oil Reservoir 60V-15FM-OR |

23 Gallon Capacity |

Hydraulic Manifold 60V-15FM-HM |

D05 Pattern, Internal Relief Valve Subplate Circuit |

Foam Film Fiber Balers - Electrical |

|

Main Motor 60V-15FM-MM |

15 HP - 208/230/460v – 3 Phase |

Enclosure 60V-15FM-EN |

NEMA 12 - Rated |

Controls 60V-15FM-CL |

UL / CUL Listed |

Motor Type 60V-15FM-MT |

TEFC High Efficiency |

Foam Film Fiber Balers - Dimensions & Structural |

|

Overall Height 60V-15FM-H |

147 |

Overall Width 60V-15FM-W |

80 |

Overall Depth 60V-15FM-D |

45 |

Depth with Door Open 60V-15FM-DO |

102 |

Frame Design 60V-15FM-FD |

10” Channel Side Rails - 12” Channel Headers |

3” x 3” Tube Steel Discharge Door Supports |

|

Solid Door Charge |

|

8 Pieces of 4” Channel in Sub Floor |

|

Feed Opening 60V-15FM-FO |

27” x 60” Charge Dimensions 23” x 60” |

Weight 60V-15FM-WT |

5,000 lbs |

Other Features of the High Memory Material Balers |

|

60V-15FM |

UL Listed (see Electrical above); Meets / Exceeds ANSI Z245.5 & OSHA Standards |

| 60V-15FM | NEMA 12 |

| 60V-15FM | Bale Height Adjustable |

| 60V-15FM | Safety Interlock Circuit on Bale Door & Safety Gate |

| 60V-15FM | Counterbalanced Feed Door for Easy Open |

| 60V-15FM | 3 – 6” Retainer Bale Dogs Front and Back |

60V-15FM |

Soft Shift, Low Shock Hydraulic Circuit |

| 60V-15FM | Dual Chain Semi-Automatic Bale Ejection System |

| 60V-15FM | Spring Doors |

| 60V-15FM | Platen Roller Guides |

| 60V-15FM | Sharks Teeth |

| 60V-15FM | Special Design for High Memory Materials |

| 60V-15FM | Factory Wired for Easy Installation |

Other Options of the Foam Film Fiber Vertical Balers |

|

Option Number |

Description |

60V-15FM-01 |

Slotted Discharge Door |

60V-15FM-02 |

Single Phase Motor (Only available on 10 HP Balers) |

60V-15FM-03 |

Front Load – Rear Eject |

60V-15FM-04 |

Oil Heater |

60V-15FM-05 |

Special Voltage – 575V |

60V-15FM-07 |

Weatherproof |

60V-15FM-08 |

Drum Crusher |

60V-15FM-09 |

Heavy Duty Package (Beefed up Frame etc) |

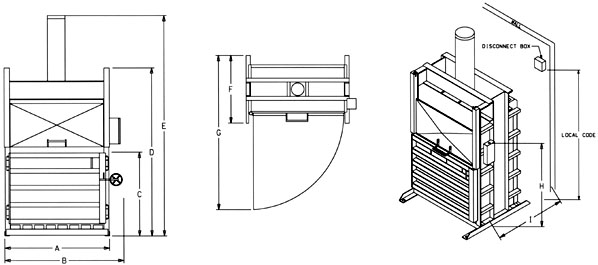

60" Foam Film Fiber Baler Diagram - 60V-15FM

A = 68" B = 80" C = 54" D = 108" E = 147" F = 45" G = 102" H = 76" I = 54"

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF