WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

Home > Sitemap > Compactors > Hopper Compactors

HOPPER COMPACTORS

Front Load or Rear Load Steel Containers are used to collect the compacted trash

HC-330 - INDOOR HOPPER COMPACTOR

Request Automated Response with general pricing - (Secure)

Request Info on Multiple Products - (Secure Area)

The Hopper Compactors are typically for indoor operation (at Street Level) near an outside wall in close proximity to where haulers can make their container tips. They can be loaded from the top, one side or both sides.

These compactors are great for trash rooms, especially those behind the walls of busy hallways (such as college residence halls) where the compactor can sit behind a wall with an access door that students can throw their trash into from the hallway (while being isolated from the compactor itself).

This Hopper Compactor works in conjunction with Front Load or Rear Load Steel Containers that are tipped onsite by Haulers. The Heavy Duty Steel Containers are on large casters for easy transport to the hauler tipping area. These Compactors are great for many applications, especially applications where ceiling height is limited. This includes Apartments, Office Buildings, Hospitals, Medical Centers, Nursing Homes and more.

When the steel container becomes full, it is simply wheeled to the hauler tipping area for pick-up. Depending upon trash volume, it is oftentimes useful to have one or more extra containers that can be used with the compactor (while the full containers are awaiting pick-up by the hauler).

The Hopper Compactors are also designed with safety and user friendliness in mind.

HOPPER COMPACTOR STANDARD FEATURES

- UL Listed Power Panel

- Meets ANSI Z245.2 standards

- Extra Large Hopper Design

- Extra Heavy Duty Containers

- Easy Connect & Latch Release of Containers

- Electrical Interlock for Operator Safety

- Key Switch, Start & Stop Buttons

- Front or Rear Load Containers

HOPPER COMPACTORS OPTIONS

(Other options may be available)

Extra Containers (either Front Load or Rear Load)

Photo-Eye 3 Position Switch

Remote Control

80% or 100% Full Light

Single or Dual Side Doors

Multi-Cycle

Oil Heater

Door Auto Start

Pressure Gauge

Oil Level Switch

Lock Valve

Hopper Cover

HOPPER COMPACTOR SPECIFICATIONS

Hopper Compactor with Steel Container Specifications -

Item HC-330 |

|

| Charge Size | 1/3 (.33) Cubic Yards |

| Motor | 3 HP TEFC |

| Electric Power | 3 PH - 208 / 230 / 460 amp / 1PH 1HP 110/220 |

| Pump | 2 Stage 5 GPM - (3 PH) or 3 GPM 1HP (1 PH) |

| Hydraulic Tank | 13 Gallons |

| Cylinder Size | 2 - Diagonal: 2'5" x 20" , 1.375" Rod |

| Packing Pressure | 15450 Normal / 17540 Max PSI |

| Ram Face Pressure | 31.3 Normal / 35.4 Max PSI |

| System Pressure | 1850 Normal / 2100 Max PSI |

| Ram Penetration | 6" |

| Cycle Time | 18 Seconds 3 HP - 29 Seconds 1 HP |

| Construction (Plate Size) | Floor & Top: 3/8"; Sides & Ram Face: 1/4" |

| Clear Top Opening | 22.5" x 28" x 24" Deep |

| Loading Height | 42" |

| Compactor Dimensions (inches) | H: 74"; W: 48"; L 41" (excluding container) |

| Container Dimensions (inches) | H: 48"; W: 40"; L: 83" |

| *Overall (Compactor + Container) | H: 74"; W: 48"; L: 136" |

| Square Footage Footprint (excludes any extra Buffer) | 42 Sq Ft |

| Actual Weight (Compactor + Container) | 1,500 Lbs. |

| *Does not include the recommended buffer for normal operation and service. | |

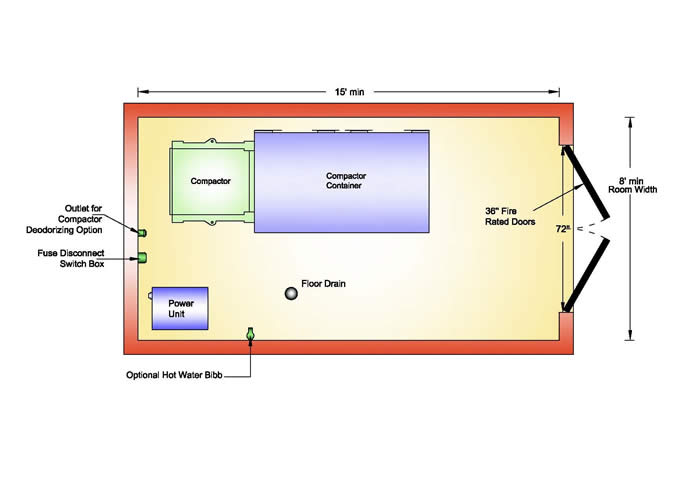

Hopper Compactor - Layout Example (Extra Container can be stored in another area)

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF