WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

Home > Sitemap > Compactors >Bin Compactors

PLASTICS COMPACTORS

(Produces Palletized Bagged Plastics)

CB-4925P - PLASTICS COMPACTOR

Jump to Sister Product > CB-2900 (Using Front / Rear Load Containers)

Request Automated Response with general pricing - (Secure)

Request Info on Multiple Products - (Secure Area)

The CB-4925P Plastics Compactors has unique features for handling plastics. This includes a heating component that is automatically controlled which warms the plastic waste material to a temperature that increases the compaction benefits, but does not compromise the integrity of the plastic so that it can be recycled. And, the Plastics Compactor can be continuously fed, and thus easily adaptable for plastics to be continuously conveyed, dumped or blown into them as a means of further streamlining waste processing routines.

And, just like the other CB-4900 series of Bin Compactors, with the CB-4925P Plastics Compactors, when the compactor signals full, the weight of the compacted cube of bagged plastics is sitting on a pallet that can easily be transported using a forklift or pallet jack. The trash placed into the CB-4925P is compacted and contained within a heavy duty polybag that measures 46" x 46" x 40". Polybags used in the CB-4925P are protected from puncture (by a metal shield mechanism that descends down into the compactor before each interim crushing process is activated). These Plastics Compactors hold roughly 2 yards of loose trash and about 12 yards of compacted trash.

Easy to Operate

The CB-4925P Plastics Compactors are also simple to operate. After placing the heavy duty bag in the compactor and closing the door, all it takes is a push of a button.

Safe to Operate

The CB-4925P Plastics Compactors have many built-in safety features such as the machine not operating if the locking door is open, emergency stop button, motor overload protection and the option to keep the loading door locked while the compactor is in operation.

CB-4925-P Compactors - Options:

|

CB-4925P - Loading Door Safety Switch

When installed, the loading door safety switch prevents the Plastics Compactor from operating when the loading (upper) door is open. (This added safety feature may not be necessary in many applications.) |

|

CB-4925P Auto-Restart Kit

With the Auto-Restart Kit your facility is able to set the intervals in which the Plastics Compactor operates and rests throughout the day. This can help reduce the overall run time and extend the life of the compactor. |

|

CB-4925P Compactor Hood. Designed to attach to the top of the Plastics Compactor, the hood serves as a cover for either exterior use or to trap dust within a shop, factory or warehouse. |

COMPACTOR SPECIFICATIONS

|

CB-4925P Plastics Compactor Specifications |

|

| Container Capacity | 1.81 Cubic Yards or about 49 Cu Ft |

| Trash Volume | Roughly 12 Cubic Yards |

| Reduction Ratio | Approximately 6 to 1 |

| Downward Pressure | Max = 600 lbs - Min = 176 lbs |

| Torque | 4,400 lbs at drum face |

| Compacted Weight | Compacted Bags - 500 - 550 lbs |

| Electric Power |

5 HP Motor 208 / 230 - 3 Phase - 14 Amps 440 / 480 - 3 Phase - 7 Amps 24 V A.C. Control Circuit Voltage |

|

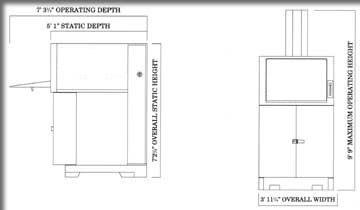

CB-4925P Compactor Dimensions |

|

| Loading Door Height | 58" |

| Static Height: | 87" (7.25') |

| Operating Height | 124" (10.33') |

| Static Depth: | 62" |

| Operating Depth: | 86" |

| Overall Width | 52" |

| Shipping Weight | Approx 3,000 lbs |

Plastics Compactors - CB-4925P Diagram

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF