WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

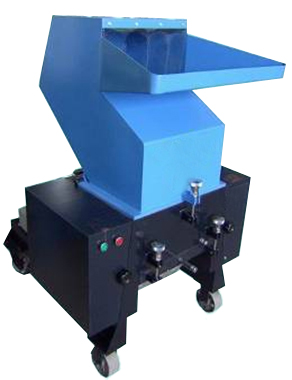

SMALL GRANULATORS, plastic grinders / PLASTIC crushers

Two Versions to fit a variety of applications

Version 1 - Great for small electronic pieces, nylon fibers, ABS, acrylic, AS and PS ......

2 VERSIONS & 10 MODELS OF GRANULATORS PLASTIC GRINDERS / PLASTIC CRUSHERS

Request Automated Response with general pricing -

(Secure) - Select Model below:

GCW-100

GCW10-Series (10 Models)

Request Info on Multiple Products - (Secure Area)

Main

Features

- Small Footprint

- Separate crushing area facilities cleaning

- Built-In Emergency Safety

Switch

- Special construction of tools for longer life

- Fast Cutter

replacement

- East Cleaning and Maintenance

- Low Noise & Speed for

low decibles environment

- Quick Screen Changes

- 3 Phase Electrical

The small granulators and plastic grinders / crushers are great for small electronic product pieces, nylon fibers, ABS, acrylic, AS and PS etc.

The resulting particle size is adjustable based on screen selections.

The primary destruction and finer granulation are accomplished at the same time which increaes work efficiency.

To read a short article about Small Grinders, Shredders & Granulators Click this link

| Imperial | Metric | |

| Main Motor | 3 HP |

2.2 KW |

| Electricity | Three Phase

460v 60 Hz |

460 v

60 Hz |

| Feed Opening | 9.8"

x 11.4" |

250 mm x

290 mm |

| Throughput / Capacity | 40 - 65 lbs / Hr | 18 - 30 kg / hr |

| RPM | 36 RPM |

36 rpm |

| Holding Size / Contents | 65 lbs | 30 kg |

| Machine Size (Rounded) |

38" x 14" x 49" |

950 mm x 350 mm x 1230 mm |

| Machine Weight | 500

lbs |

230 kg |

Small Granulators are great for slant & flat scrap, injection molding scrap, plastic bottles and small boxes. Granulators grind the material into small chips.

The small footprint, low noise, low

cost design allows the Granulators to be strategically placed at work

station areas where waste is being generated.

Version 2 - Great for plastic bottles, containers, injection molding spurs and extrusion parts

| 10 MODELS OF SERIES GCW GRANULATORS, PLASTIC GRINDERS, PLASTIC CRUSHERS | |||

|

|

||

Small Granulators are great for all kinds of plastic bottles, containers, plastic sheets, spurs from injection molding and extrusion parts, PVC and nore. Granulators grind the material into small chips that are approximately 1 / 4" to 1 / 2" in diameter.

Small Granulators can be strategically placed at work station areas where waste is being generated due to the small footprint, low noise, low cost design.

To read a short article about Small Grinders, Shredders & Granulator Click this link

| GCW-150 | GCW-250 | GCW-350 | GCW-450 | GCW-550 | |

| Motor | 3 HP / 2.2 kw | 5 HP / 4 kw | 7.5 HP / 5.5 kw | 10 HP / 7.5 kw | 15 HP / 11 kw |

| Electrical / Power | 3 ph 208/230/460 60Hz | 3 ph 208/230/460 60Hz | 3 ph 208/230/460 60Hz | 3 ph 208/230/460 60Hz | 3 ph 208/230/460 60Hz |

| Throughput

'up to' ( lbs / hour) |

220 - 330 lbs / hr | 285 - 450 lbs / hr | 485 - 650 lbs / hr | 775 - 1,100 lbs / hr | 1000 - 1325 lbs / hr |

| Cutting Chamber Opening | 7.2" x 5.9" | 9.8 " x 8.7" | 12.6" x 9.4" | 16.5" x 10.8" | 20" x 12 " |

| Resulting Particle Size (Approx) | 1 / 4" / 6 mm | 1 / 4" / 6 mm | 1 / 3" / 8 mm | 1 / 3" / 10 mm | 1 / 2" / 12 mm |

| Rotor Blades (PCS) | 9 | 6 | 9 | 12 | 15 |

| Stationary Blade (PCS) | 2 | 2 | 2 | 2 | 2 |

| Machine Size | 27" x 18.5" x 35.4 | 36" x 27" x 41" | 43" x 30" x 45" | 44" x 34" x 52" | 53" x 40" x 57" |

| Machine Weight | 350 lbs | 675 lbs | 812 lbs | 925 lbs | 1450 lbs |

| Application | see description | see description | see description | see description | see description |

| GCW-650 | GCW-750 | GCW-850 | GCW-950 | GCW-1050 | |

| Motor | 20 HP / 15 kw | 30HP / 22 kw | 40 HP / 30 kw | 50 HP / 37 kw | 50 HP / 37 kw |

| Electrical / Power | 3 ph 208/230/460 60Hz | 3 ph 208/230/460 60Hz | 3 ph 208/230/460 60Hz | 3 ph 208/230/460 60Hz | 3 ph 208/230/460 60Hz |

| Throughput

'up to' ( lbs / hour) |

1325 - 1750 lbs / hr | 1800 - 2000 lbs / hr | 1800 - 2000 lbs / hr | 2200 - 2700 lbs / hr | 2200 - 2700 lbs / hr |

| Cutting Chamber Opening | 24.4" x 13.4 " | 28" x 13.5" | 31.5 " x 20" | 35.5" x 20" | 39 x 24" |

| Resulting Particle Size (Approx) | 1 / 2" / 12 mm | 1 / 2" / 6 mm | 1 / 2" / 6 mm | 1 / 2" / 8 mm | 1 / 2" / 10 mm |

| Rotor Blades (PCS) | 18 | 21 | 24 | 27 | 30 |

| Stationary Blade (PCS) | 4 | 4 | 4 | 4 | 4 |

| Machine Size | 62" x 44" x 66" | 71" x 50" x 56 | 87" x 55" x 87" | 87" x 59" x 84" | 59" x 57" x 88" |

| Machine Weight | 1800 lbs | 2200 lbs | 4500 lbs | 5000 lbs | 6200 lbs |

| Application | see description | see description | see description | see description | see description |

| Note: The quantity of bottles per hour was derived by using 20 PET bottles per pound as a basis. |

Note: Specifications, Dimensions & other product details may vary upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice. Performance may vary depending upon application. Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF