WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

Home > Sitemap > Compactors > Thru the Wall Compactors

'SITE FRIENDLY' THRU-the-WALL COMPACTORS - FRONT LOAD & REAR LOAD

3,4,6, & 8 Yard Front Load or Rear Load Containers for Thru-The-Wall applications

TWS-2000 Series SITE FRIENDLY Thru-the-Wall COMPACTOR

Request Automated Response with general pricing- (Secure)

Request Info on Multiple Products - (Secure Area)

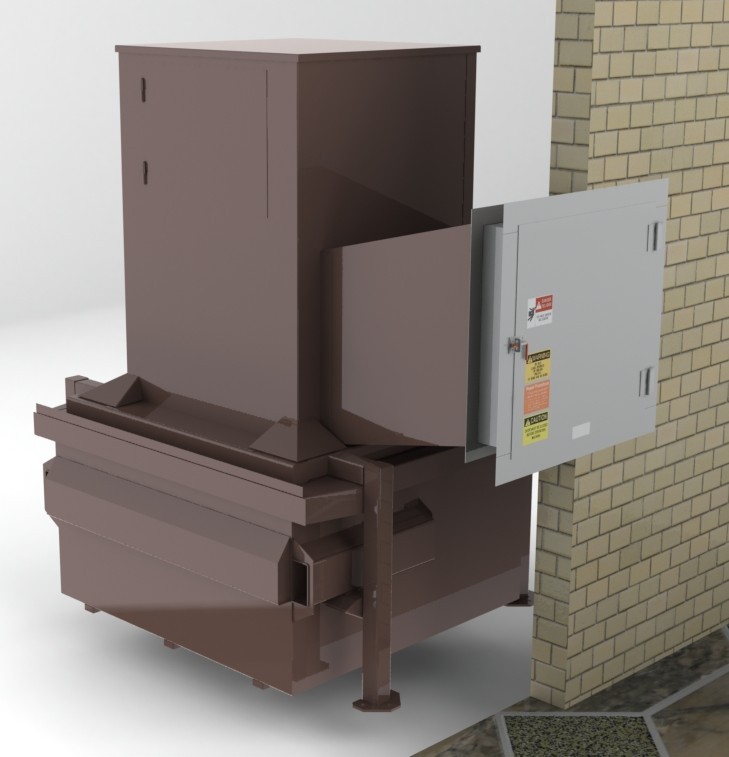

The Site Friendly Thru-the-Wall Compactors are outdoor compactors that can be fed from inside using a chute that is attached to the machine sitting on the outside. In addition these Thru-the-Wall Compactors can be loaded by the Hauler from any of the 3 remaining sides (after excluding the side that the chute feed is located on). These Compactors can also be easily adapted to load from a dock, off the ground or combined with an open chute.

The Site Friendly Thru-the-Wall Compactor works in conjunction with Front Load or Rear Load Containers that are tipped onsite by Haulers. These Compactors are great for many applications, especially applications such as Office Buildings, Apartments, Hospitals, Medical Centers, Nursing Homes and more.

When the steel container becomes full, it can be tipped just like any other outdoor compactor.

SITE FRIENDLY THRU-the-WALL COMPACTOR STANDARD FEATURES

- UL / CUL Listed Control Panel

- Meets ANSI Z245.2 standards

- Controls are Key Operated

- Integrated Power Unit

- Chute Kit with Door Sleeve & Remote Control Panel (on Thru-the-Wall Configuration)

- Compactor has legs that can be vertically adjusted to allow for 5 different container sizes

- Hydraulic Lines are not attached to the container which means hauler does not have to exit the truck

- The design of the Feed Access door helps eliminate trash from accumulating on top of the compaction mechanism

- Front or Rear Load Containers

STANDARD THRU-the-WALL COMPACTOR OPTIONS

(Other options may be available upon request)

Extra Containers (either Front Load or Rear Load)

Single Phase 230v 60Hz - 1.5 HP)

Oil Heater

SITE FRIENDLY THRU-the-WALL COMPACTOR SPECIFICATIONS

Thru-the-Wall Compactor Specifications - TWS-2000

Series |

|

| Charge Size | 2 Cubic Yards |

| Motor | 3 HP |

| Electric Power | 3 PH - 208v / 230v / 460v 60Hz |

| Pump | High / Low Gear |

| Pump Capacity | 8 gpm @ 1800 rpm |

| Tank Capacity | 8.5 Gallons |

| Cylinder Size | Two 3" Bore - Rod: 2" - Stroke: 37.25" |

| Packing Pressure | 24,700 lbs |

| Ram Face Pressure | 13 PSI |

| Operating Pressure | 2000 PSI |

| Ram Penetration | 10" |

| Cycle Time | 30 Seconds |

| Construction Container | Floor: 11 ga - Sides: 11 ga - Channel: 3" - Sq Tube: 11 ga 1.5" x 1.5" |

| Construction Presshead | Face: 1/4" Steel Plate - Sides: 7 ga - Guides:UHMW Strips |

| Construction Chassis | Steel Tube Frame; 11 ga Sheet Steel Shroud |

| Clear Top Opening | 37.25" L x 38" W |

| Feed Height | See Chart Below |

| Compactor / Container Dimensions (inches) | See Chart Below |

| Actual Weight (Compactor + Container) | 4,000 - 4,500 Lbs. (depending on Container) |

| *Does not include the recommended buffer for normal operation and service. | |

Compactor and Container Dimensions Chart |

||||||

Description |

Compactor

Charge Size |

Feed Height |

Overall Height |

Container Size |

Container Height |

Item |

3 Yd Front Load |

2 Yard |

40" |

112 1/2" |

3 Yard |

35 13/16" |

TWS-23-F |

4 Yd Front Load |

2 Yard |

46 1/4" |

118 5/8" |

4 Yard |

41 3/4" |

TWS-24-F |

4 Yd Rear Load |

2 Yard |

46" |

118 5/8" |

4 Yard |

46 5/8" |

TWS-24-R |

5 Yd Front Load |

2 Yard |

56 1/4" |

128 5/8" |

5 Yard |

51 7/8" |

TWS-25-F |

6 Yd Front Load |

2 Yard |

56 1/4" |

128 5/8" |

6 Yard |

51 7/8" |

TWS-26-F |

8 Yd Front Load |

2 Yard |

74" |

146 3/8" |

8 Yard |

69 1/5" |

TWS-28-F |

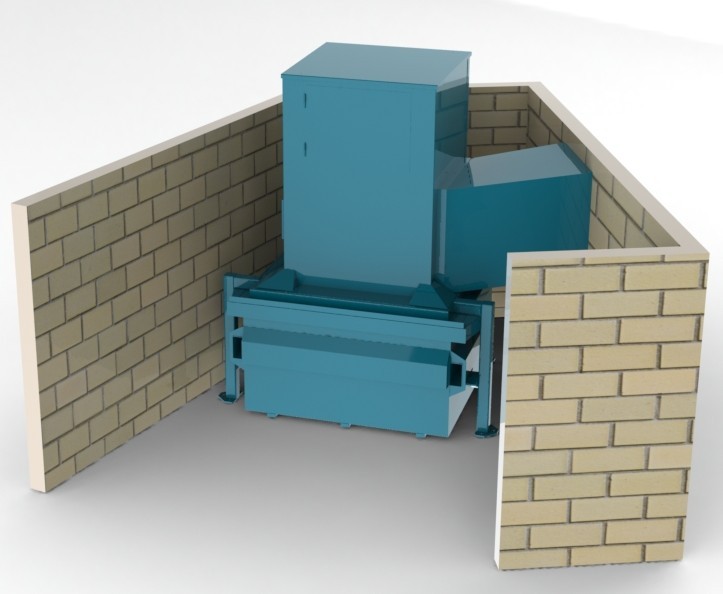

Site Friendly Thru-The-Wall Compactor - Layout Example

Dimensions may be rounded (and unless indicated) do not include any recommended 'perimeter buffer

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF