WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

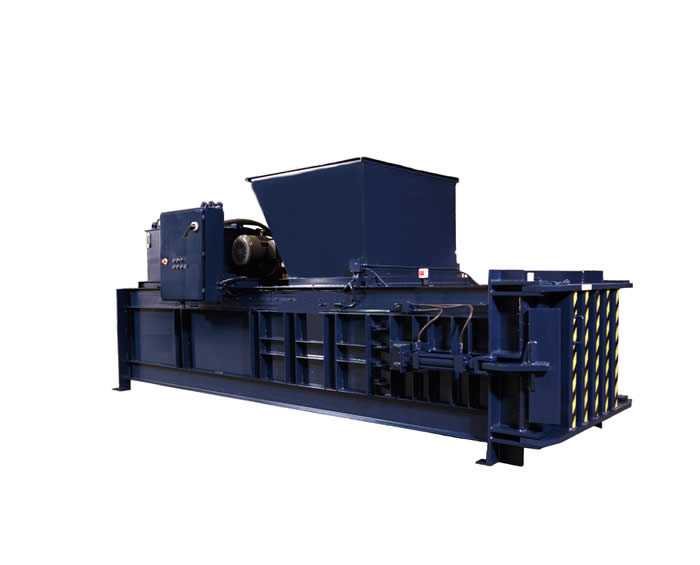

FE50-5923 HORIZONTAL FULL EJECT BALER

This Horizontal Baler is ideal for:

- Municipalities

- Distribution Centers

- Manufacturing Facilities

- Recycling Centers

- Warehouses

- Scrap Yards

- Shopping Centers

- Transfer Stations

- Many other types of Industrial / Commercial Applications

FE50-5923

To jump to the Comparison Chart on all Full Eject Horizontal Balers

Request Detailed Quote or other information - (Secure Area)

Request Automated Response with general price information

This Full Eject Horizontal Baler is loaded with awesome power and features for High Volume, Multi-Material Baling Applications and built to provide many years of durable service in the toughest environments.

Bales a variety of materials including:

- Bulk Corrugated

- Bulk ONP

- Used Beverage Cans

- PET

- Aluminum Sheet & Ext.

- Metals

- More....

In addition to maximizing bale weights and sizes, all balers are designed and produced with many other customer satisfaction factors in mind such as:

- Reducing waste disposal costs while minimizing acquisition and start-up costs of waste handling equipment

- Reducing labor costs

- Streamlining overall waste processing operations for better productivity

- Durability and reliability

- Improving cleanliness and business image

- Improving workplace safety

- Achieving quick paybacks

Whether it is baling cardboard, plastics, metals, magazines, or other materials, the design, components and construction is meant to produce many years of trouble-free economical service for our customers.

Baler Performance |

|||

Bale Size |

48” x 30” x 60” |

||

Bale Volume |

50 Cubic Feet |

||

Cycle Time |

23 Seconds |

||

Estimated Bale Weights |

|||

Material |

Bale Weight |

Density Lbs/Cu Ft – Loose/Baled |

30 HP Bales / Hr |

Bulk OCC |

Up to 1,450 Lbs |

2.5 / 28 |

Up to 3 |

Bulk ONP |

Up to 1,500 Lbs |

3 / 30 |

Up to 3 |

Aluminum Sheet & Ext. |

Up to 1,800 Lbs |

4 / 36 |

Up to 3 |

Used Beverage Cans |

Up to 700 Lbs |

1 / 14 |

Up to 3 |

PET |

Up to 750 Lbs |

1.5 / 15 |

Up to 3 |

Note: Performance Rates, Bale Weights, and Bale Densities are subject to many factors such as Material Pre-Bale Densities, Feed rates, Moisture Content and other variables. |

|||

Hydraulics |

|

Main Pumps |

106 GPM - Double Vane - 1 @ 75 GPM (800PSI) & 1 @ 31 GPM (2600 PSI) |

System Pressure |

2600 PSI / 3000 PSI Maximum |

Main Cylinder |

9” Bore, 6” Rod, 92” Stroke |

Ram Face Pressure |

101.85 PSI - 111.54 at Maximum |

Overall Platen Force |

165,405 Lbs - 190,852 Overall |

Oil Reservoir |

400 Gallon Capacity |

Hydraulic Manifold |

Integral Relief - Regenerative Hydraulic Circuit |

| Filtration | 6 Micron |

| Directional Valve: | 2 - DO8 |

| Air / Oil Cooler: | Standard |

Electrical |

|

Main Motor |

50 HP - 230/460v – 3 Phase (Standard) |

Enclosure |

NEMA 12 - Rated |

Controls |

UL Approved - CUL & UL Listed |

Motor Type |

TEFC - Heavy Duty - Greased fittings & bearings & totally enclosed fan coolers |

| PLC | Allen Bradley SLC500 |

Structural |

||

Frame Design |

Tube Steel Construction | |

Floor Design |

Tube Steel Lattice Network | |

Shear Blade |

T-1 Alloy Steel, Serrated Split Blade Sheer | |

Platen Guides |

Tongue & Groove Floor Guides & Adjustable Platen Hold Down | |

| Linen Phenolic Wear Side Guides | ||

| T-1 Top Wear Guides | ||

| Gib Bars | A-1018 | |

| Shipping Weight | 26,000 lbs (Approximately) | |

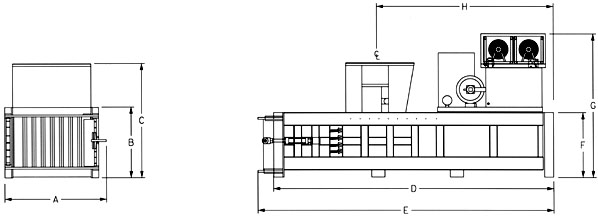

Baler Dimensions - Note: Specifications are sometimes rounded within a few inches +/- |

|

Overall Height |

195" |

Overall Width |

125" |

Length |

325" |

| Feed Opening | 60" W x 45" L |

| Note: Dimensions include standard Conveyor option but not Hopper extensions or 'perimeter buffer' | |

Other Baler Features (Note: Some items may be options if specified) |

| Product meets or exceeds all ANSI Z245.5 and OSHA standards. |

| Product has NEMA 12 |

| All Cylinders are trunion mounted for a stronger mount and more protection for the cylinder |

| All machines are shipped with hydraulic fluid in them |

| Regen Hydraulic Circuit for adding more speed to the system by bringing more fluid to cylinder |

| Air/Oil Cooler helps prevent the hydraulic oil from overheating (on all models except the 20HP) |

| Tongue and Groove Flooring helps keep material from getting under the platen |

| Wide Mouth In-Feed Openings for variety of materials and sizes |

| Automatic cycling, activated by electric eye in hopper feed chute |

| Safety interlocks which means the baler automatically stops when door or panel is opened |

| Rugged, reinforced baling chamber and door |

| Oversized locks, hinges and hydraulic components helps keep maintenance costs low |

| Lock-out Tag-Out provisions are incorporated |

Main Baler Options |

|

Option |

Description |

01 |

Remote Power Unit |

02 |

Hopper Extension |

03 |

Foam Hopper |

04 |

Ultra Sonic Actuator |

05 |

High Intensity Actuator |

06 |

High Temperature / Low Oil Level Alarm |

07 |

Soft Start - Reduced Amperage Starting |

08 |

Upper Photo Eyes |

| 09 | Finger Safe Fuse Guards |

| 10 | Weatherproof |

| 11 | Oil Heater |

| 12 | Special Paint |

| 13 | Special Voltage |

| 14 | Slotted Discharge Door (Slotted Vertically) |

| 15 | Conveyors |

| 16 | Conveyor & Cart Dumper Controls (for existing Conveyor or Cart Dump) |

| 17 | Cart Dumper |

| 18 | Bale Run Out Table |

Horizontal Dimension Diagram:

A |

B |

C |

D |

E |

F |

G |

H |

|

FE50-5923 |

78 |

54.75 |

88 |

222 |

254 |

49.5 |

110 |

145 |

| Note: Specifications are sometimes rounded within a few inches or more - If necessary, confirm before order placement | ||||||||

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF