WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

STYROFOAM BALER

60" Vertical Baler

Polystyrene (commonly known as Styrofoam - which is a trademark of the Dow Company), is all around us. It is commonly used as packing material (peanuts). Food trays, cups and many other products are made of polystyrene. Products containing polystyrene usually have a recycling triangle logo with the number 6 inside it stamped on the item. If polystyrene is something you get a lot of; you might be able to sell it. This 60" baler is your way to package it for resale or recycling.

60V-15ST - BALER FOR STYROFOAM

Request Automated Response with general pricing - (Secure)

Request Info on Multiple Products - (Secure Area)

With it's unique features, this 60" Styrofoam Baler is ideal for:

- Manufacturing Facilities

- Packaging and Shipping Facilities

- Department Stores

- Shopping Centers

- Colleges & Universities

- Grocery Stores / Supermarkets

- Hotels / Motels

- Military Bases

- Many other types of Industrial / Commercial Applications.

The Styrofoam Baler has many important design features that separate it from other balers.

- When compared to a cardboard baler (trying to do the job of a Styrofoam Baler) these Styrofoam balers can properly handle and eject the styrofoam bales, whereas a standard cardboard baler cannot.

- The Styrofoam Vertical Balers use a specially designed configuration for overcoming the memory retention of the styrofoam material. A standard cardboard baler cannot handle this properly.

- A Special chamber design is also incorporated in order to permit easier and smoother bale ejection. This modified design is another feature that sets these Styrofoam Balers apart from the typical baler.

- The Styrofoam Balers also have a special arrangement of Retention Dogs not found on typical balers.

- In addition to the this basic overview, there are several other differences in the design of the Styrofoam Balers that make them unique (some of which are proprietary features).

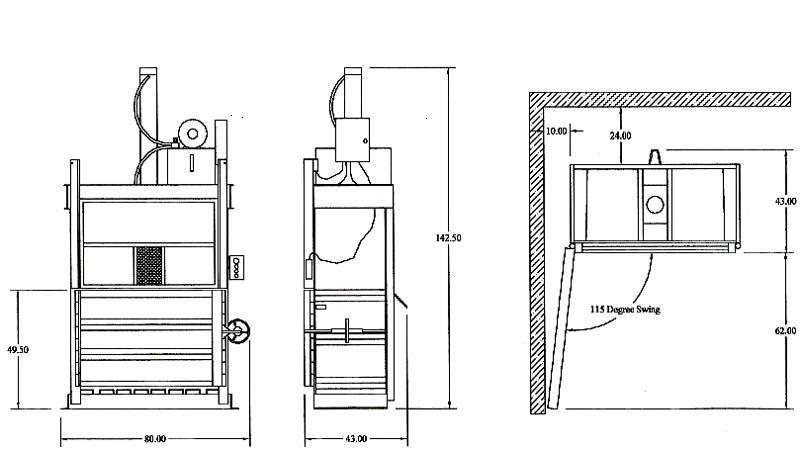

Styrofoam Baler - Specifications and Dimensions

Styrofoam Baler Specifications |

|

| Electrical: | 3 Phase - 208V / 230V / 480V |

| Bale Size: | 60 x 30 x 48 |

| Overall Platen Force: | 56,548 lbs |

| Cylinder: | 6" Bore; 48" Stroke |

| System Pressure: | 2000 PSI |

| Bale Weight: | Styrofoam - Up to 350 lbs - Corrugated - Up to 1,000 lbs |

| Motor: | 15HP - TEFC High Efficiency - NEMA 12 |

| Pump: | 15 GPM - Fixed Vane Volume |

| Power Unit: | Submersible |

| Tank Capacity: | 20 Gallons |

| Cycle Time: | 37 Seconds |

| Feed Opening: | 27" x 60" |

| Overall Height: | 143" |

| Depth: | 43" |

| Overall Depth (wih door open): | 105" |

| Overall Width: | 80" |

| Shipping Weight: | Approximately 5,000 lbs |

Other Features of the Styrofoam Balers |

| ETL Listed & Meets ANSI Z245.5 |

| Counter Balanced Feed Door - 'Easy Open' |

| Safety Interlock Circuit on Bale Door and Safety Gate |

| Soft Shift, Low Shock Hydraulic Circuit |

| Custom Bale Ejection System for Styrofoam |

| Customized Chamber for Styrofoam |

| Special Retention Dogs |

| Designed for easy installation |

| Semi-Automatic Ejector System |

Other Options of the Styrofoam Balers |

|

Option Number |

Description |

60V-15ST-SU |

Set-Up (Conditions applicable, such as electrical, floor pad, operating area etc by customer) |

60V-15ST-01 |

Slotted Discharge Door |

60V-15ST-02 |

Single Phase Motor |

60V-15ST-03 |

Full Bale Light |

60V-15ST-04 |

Oil Heater |

60V-15ST-05 |

Front Feed Chute |

60V-15ST-06 |

Rear Feed; Front Eject |

60V-15ST-07 |

Rear Feed Wire Guide |

60V-15ST-08 |

Weather Cover |

60V-15ST-09 |

Floppy Dogs |

60V-15ST-10 |

Custom Color |

Styrofoam Baler - Diagram - 60V-15ST

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF