WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

HIGH DENSITY ECONOMY BALER - 60" Vertical

60-E615 - 60" HIGH DENSITY ECONOMY BALER

Request Automated Response with general pricing - (Secure)

Request Info on Multiple Products - (Secure Area)

This High Density Economy Baler is a great selection for a variety of recycling materials.

This 60" High Density Economy Baler is ideal for:

Retail Stores

Manufacturing

/ Factories

Resorts / Motels / Hotels

Grocery Stores

Department Stores

Shopping Malls

Universities, Colleges, Schools

Military Facilities

Many other applications for Industrial / Commercial

Comparison Chart on 60" Vertical Balers

60" High Density Economy Vertical Baler Performance Information |

||||

Bale Size |

60-E615-BS |

30” x 48” x 60” |

||

Bale Volume |

60-E615-BV |

50 Cubic Feet |

||

Cycle Time |

60-E615-CT |

46 Seconds |

||

Estimated (Up to) Bale Weights |

||||

Material |

Bale Weight |

Density Lbs/Cu Ft – Loose/Baled |

Bales / Hr |

|

OCC - Cardboard |

1,100 Lbs |

2.5 / 24 |

Up to 2 |

|

Shredded ONP - Newspaper |

1,100 Lbs |

2.5 / 26 |

Up to 2 |

|

Plastic / Shrink Wrap |

750

- 800 Lbs |

1.5 / 14 |

Up to 2 |

|

| Clothes | 500 Lbs | 4 / 10 | Up to 2 |

|

Note: Performance Rates, Bale Weights, and Bale Densities are subject to many factors such as Material Pre-Bale Densities, Feed rates, Moisture Content and other variables. |

||||

60" High Density Vertical Baler - Hydraulics |

||

Main Pumps |

60-E615-MP |

12.8 GPM |

System Pressure |

60-E615-SP |

2400 PSI Maximum; 2200 PSI Operating |

Main Cylinder |

60-E615-MC |

6” Bore; 3.5" Rod; 48” Stroke |

Ram Face Pressure |

60-E615-FP |

38 PSI |

Overall Platen Force |

60-E615-PF |

67,857 Lbs Max ; 62,202 Lbs Normal |

Oil Reservoir |

60-E615-OR |

22 Gallon Capacity |

60" High Density Vertical Baler - Electrical |

||

Main Motor |

60-E615-MM |

15 HP - 208 / 230 / 460v – 3 Phase |

Controls |

60-E615-CL |

ETL Listed |

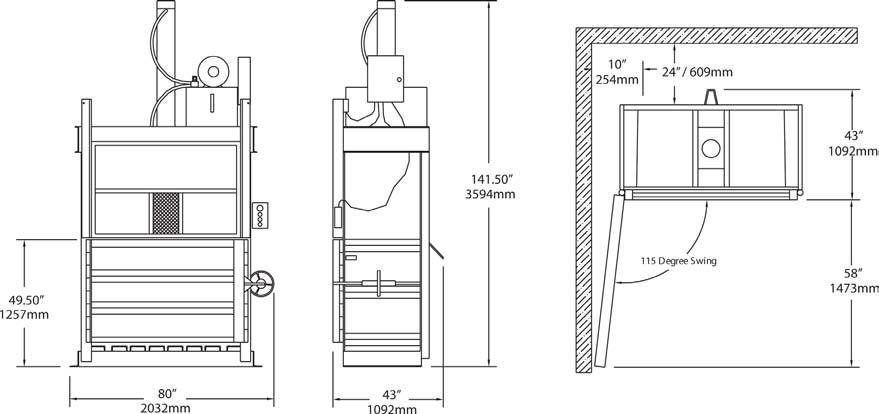

60" High Density Vertical Baler - Dimensions & Structural |

||

Height |

60-E615-H |

143 |

Width |

60-E615-W |

80 |

Depth |

60-E615-D |

45 |

Depth (Door Open) |

60-E615-DO |

102 |

Feed Height |

60-E615-FO |

49.50” |

Weight (Approx) |

60-E615-WT |

5,000 lbs |

Other Features of the 60" High Density Baler |

|

| 60-E615 | ETL Listed (see Electrical chart above) |

| 60-E615 | Product meets or exceeds all ANSI Z245.5 and OSHA standards. |

| 60-E615 | Safety Interlock |

| 60-E615 | Ejector System - Semi-Automatic |

| 60-E615 | Full Bale Switch |

| 60-E615 | 6 Bale Tie Slots |

| 60-E615 | Factory Wired for Easy Installation |

| 60-E615 | Structural frames reinforced in high stress areas, plus other heavy duty 'extras'. |

Other Options of the 60" High Density Economy Vertical Baler |

|

| 60-E615-SU | Set-Up |

| 60-E615-01 | Special Electrical - Single Phase Motor (Only available on 10 HP Balers) |

| 60-E615-02 | Slotted Door (Best use is shredded material in which bale can be tied tied off before opening door) |

| 60-E615-03 | Full Bale Light (Otherwise just two arrows for up and down of platen) |

| 60-E615-04 | Front Feed Chute |

| 60-E615-05 | Rear Feed Opening, Front Eject |

| 60-E615-06 | Rotary Disconnect (For very strict electrical requirements versus standard fused disconnect) |

| 60-E615-07 | Oil Heater |

| 60-E615-08 | Floppy Retainer Doggs (Used mostly on balers that are used for foam rubber or carpet pad type material) |

| 60-E615-09 | Weather Cover |

| 60-E615-10 | Wire Guide System (allows for front bale tie off) |

| 60-E615-11 | Lovejoy Coupling (Easily replace either Pump or Motor versus having to replace both if one fails) |

| 60-E615-12 | Special Paint |

| 60-E615-20 | Rear Feed Chute Package - Makes Baler Conveyor Ready (Rear Clamshell with Photo-Eye) |

| 60-E615-21 | Rear Feed Chute Package with Conveyor (Rear Clamshell with Photo-Eye and Conveyor) |

60" High Density Economy Baler Diagram

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF